About us

We’re here to simplify material sourcing – and the team behind our name is stellar beyond measure. We’re proud of all we’ve accomplished over these last few years – and we’re only just getting started.

About us

We’re here to simplify material sourcing – and the team behind our name is stellar beyond measure. We’re proud of all we’ve accomplished over these last few years – and we’re only just getting started.

What we are about

Material Exchange is transforming the way the fashion industry sources materials and products to be more efficient, transparent, and sustainable.

We achieve this through our state-of-the-art Digital Sourcing Platform and services, which allow material suppliers to showcase their materials more effectively to fashion brands, and fashion brands to find the materials they need in a fraction of the time.

A new approach to sourcing

It all started in 2018 when a group of industry professionals reimagined the process of sourcing materials for footwear and apparel. From this idea came a sourcing platform in which brands and suppliers could connect. Fast forward a couple of years through some evolution stages and we come to our Digital Sourcing Platform (DSP). This is making material sourcing more effective than ever before – and it’s impacting the entire industry.

Our team

We’re a global team of 70+ digitization experts focused on footwear and apparel with backgrounds in sustainability, material sourcing, and more. Our team is growing and currently spread across seven countries: Sweden, USA, Serbia, Armenia, India, China, and the UK, plus additional remote locations.

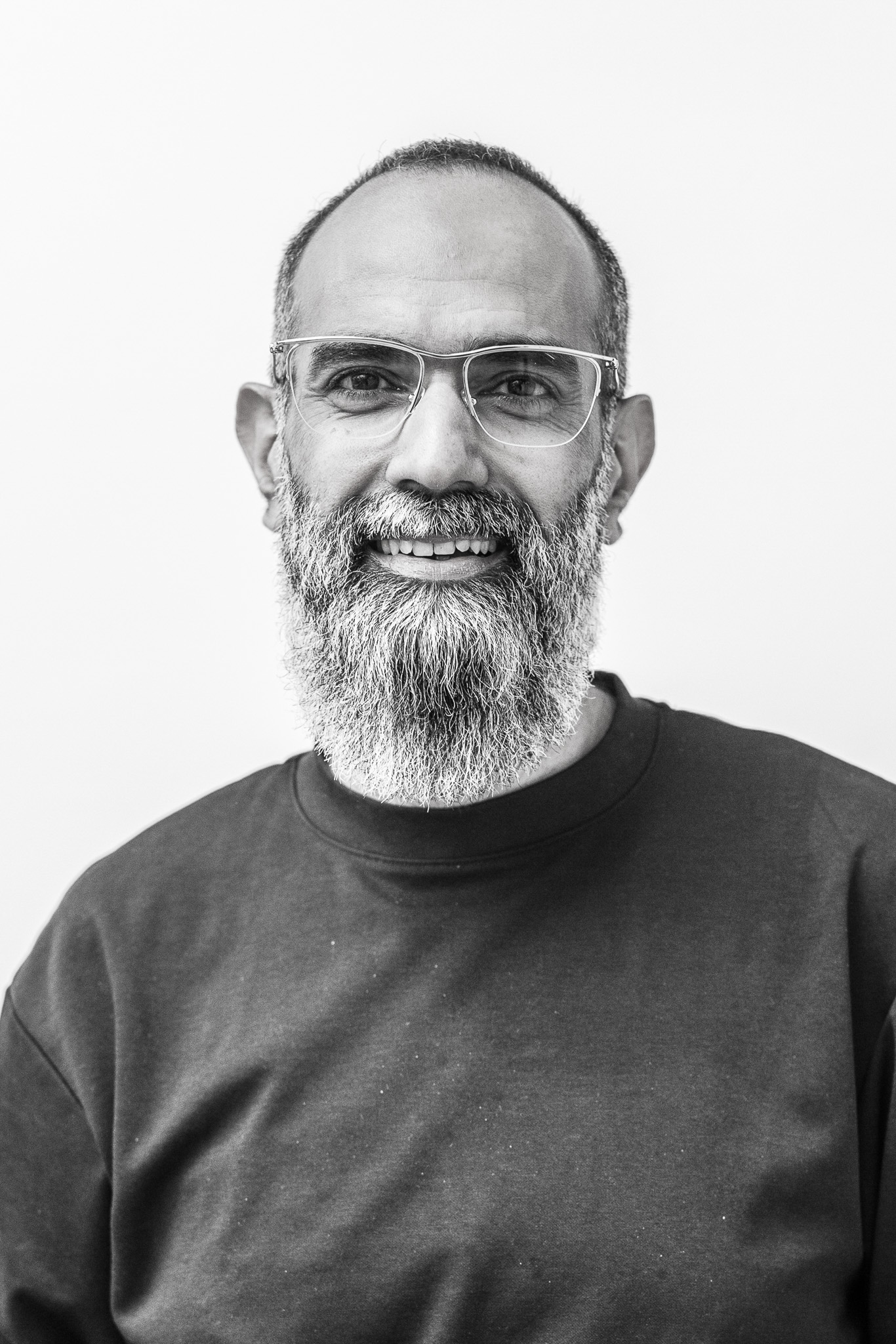

Darren Glenister

Chief Executive Officer

Ben Felton

Chief Strategy & Marketing Officer

Dora Lality

Chief Legal Officer

Andrew Olah

Chief of Textiles

Robert Conway

Chief Product & Technology Officer

Zaki Saleemi

Senior Vice President of Global Sales

Dejan Zvekic

Chief of Digitization

Emily Olah

VP Strategic Partnerships

Where to find us

Head office

Material Exchange Venture AB

c/o Convendum

Birger Jarlsgatan 57

113 65 STOCKHOLM

Additional office locations

New York, US

Subotica, Serbia

Yerevan, Armenia

Mumbai, India

Dongguan, China

London, UK

Investors who make a difference

In late 2020, we completed an investment round of €6 million led by Norrsken VC to help us grow and achieve our long-term goals. In Q1 2022, we closed a €25 million round of funding led by world-class investor Molten Ventures along with the continued support of previous seed investors including Partech, Norrsken, Inventure, Day One Capital, and Lyra.

Want to chat?

We’d love to hear from you. Reach out to see how we could work together.