Frank is a bear - but he's not just any old bear. He's a bear who knows...

Material Scanning Can Unlock New Opportunities for Suppliers

- By Lauri Kokkila

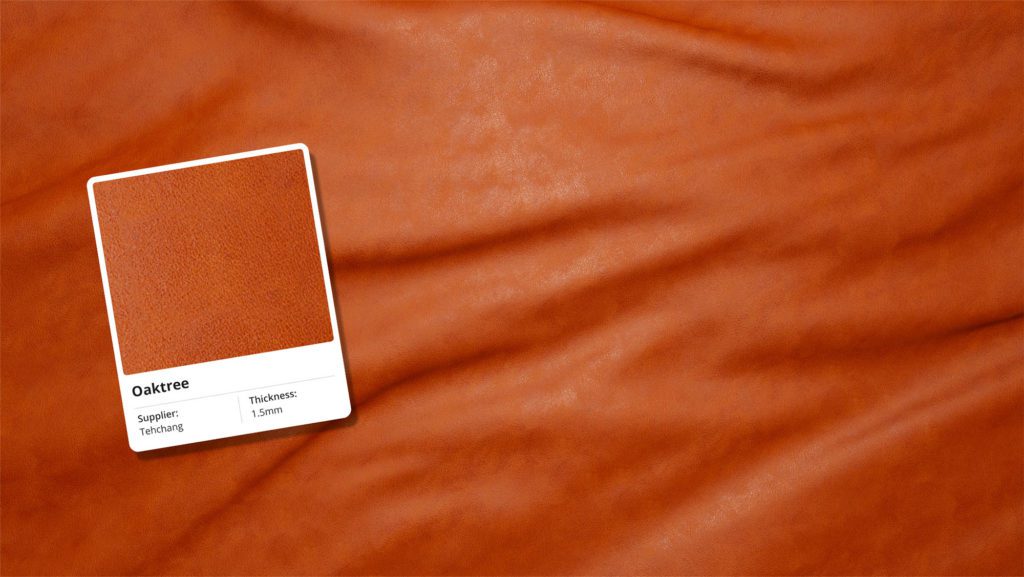

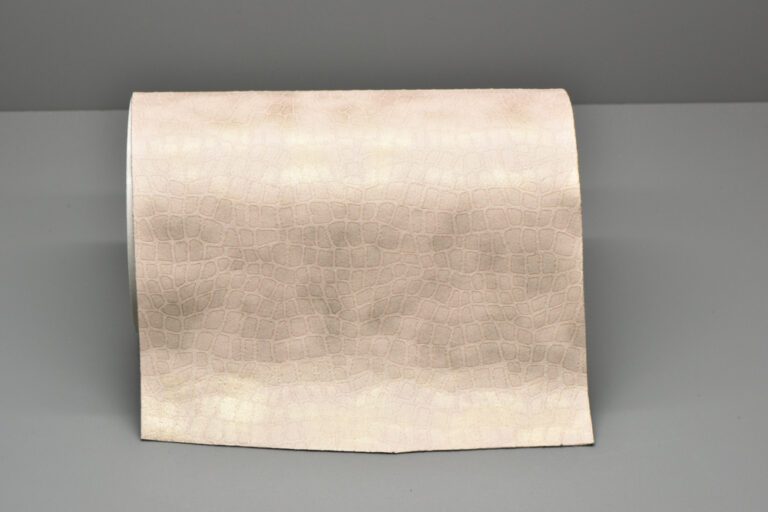

In the interest of transparency and product knowledge to benefit end-customers, buyers today want to know specific information from suppliers, such as material weight, fibers, finish, and more. It’s important for suppliers to share high-resolution images to help buyers know about the qualities of a particular textile, leather, or component. It’s just as important to share supplier certifications around sustainability, industry awards, business profile, and contact information for credibility and to conduct business.

“We see the incorporation of digital material samples will significantly decrease unnecessary material waste which occurs during the development process. This is the most meaningful benefit of Material Exchange – it enables us to continue our commitment to protecting the planet for future generations.”

Tiong Liong Industrial Co., Ltd.

The material sourcing industry, like every other in today’s digital business landscape, needs to accommodate customer expectations for service. Buyers expect digitally-enabled sales where they can get answers on their own before talking to a supplier. Buyers expect current information with accurate data about textile characteristics and features. And buyers expect to be able to satisfy their customers’ need for faster fashion.

Altogether, this has set the stage for suppliers to digitize their materials for doing business better. It’s important for suppliers to simplify their material management process, maintain information about their inventory, and make it easy for buyers to find them from anywhere in the world. Leveraging technology to help address all these business needs is the most cost-effective way to be where buyers are looking for materials.

While many suppliers are tech-ready, some suppliers are not tech-savvy to meet these industry demands. In either case, Material Exchange was built from the ground-up to support suppliers in growing their business globally.

“Material Exchange provides an excellent service. The customer support staff are very polite and very patient in guiding us on how to use the platform. They are also very helpful to quickly solve the problem. The scanning services are also very good!”

– Fujian Honggang Textile Technology Co., Ltd.

The good news is that the supplier does not need a camera, fancy lighting, or lightbox equipment to create high-quality images of their materials. Material Exchange offers suppliers a simple way to digitize their materials.

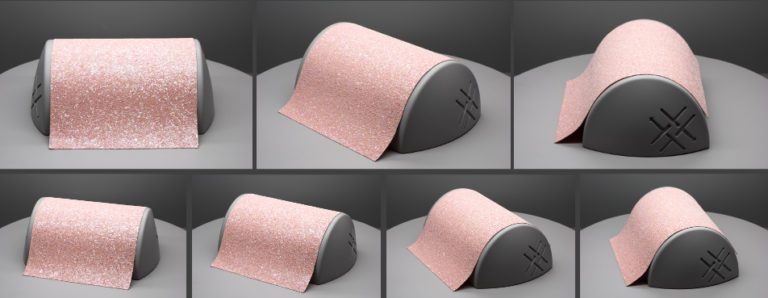

First, the supplier makes a request for the type of scanning they need, which might be a photograph, turntable photograph, video, or 3D scan. Second, the supplier sends their samples to the nearest Material Exchange regional scanning hub. Third, the supplier’s samples are scanned and converted into their preferred digital format. Lastly, those digital assets are uploaded into the supplier’s profile, which means they are now available throughout the Material Exchange global marketplace.

To see samples of the digital scans available to suppliers or to order scans, please visit about scanning here.

We know this can feel like a lot of work, but we’re here to support you through the process. If you have any questions at all about our scanning services or scanning in general, please feel free to reach out to us here. Let’s digitalize material sourcing for a better tomorrow!

About the author

Lauri Kokkila, VP of Growth at Material Exchange, is responsible for developing and scaling Material Exchange’s Scanning Service globally.

Check out our webinar on digitizing

Related content

The Deadstock Debut's presence at the Kingpins Show Pop-up Event in Hong Kong has been marked by...

While fashion is often seen as an edgy, innovative industry, its digitization has been much slower than...

3D product development may not be a new concept, but its wide-spread adoption across the fashion industry...