Sourcing footwear and apparel materials has historically been time-, travel-, and resource-heavy; the time has come to streamline the material sourcing value chain with technology.

Traditionally a belly-to-belly transaction, the process of sourcing and then managing materials has been analog-based and relied on multiple, separate systems. This has resulted in a slow and complex go-to-market journey; our recent survey (source: Digital Sourcing Report) shows it can take up to 40 weeks – nearly a year! – to source materials and get a product to market. However, we no longer have the luxury of ‘sourcing as usual’ because business in general has responded to greater market forces.

Some of the specific factors that have recently impacted the sourcing process for footwear and apparel materials supply chains include: the pandemic, new horizons in technological capabilities, dynamic materials trends, the need to streamline the process and reduce expenses, a new reliability on cohesive data to drive business and product development effectively, evolving buyer preferences and emerging requirements on sustainability. Material sourcing, like every other business, is being driven to change in response to, and ideally lead, the industry in delivering savvier performance and results.

The market disruption of 2020 highlighted the areas and processes of the footwear and apparel industries that need significant transformation. Research shows 55% of brands still rely on 2D designs; however, much of the workflow has become digital, bringing 3D design to the forefront. According to our annual survey, 72% of buyers value 3D imaging and, yet, less than 10% of suppliers offer 3D visuals of their materials. Digital scans can reach more potential buyers around the world, at the speed of the internet and, as a result, are a significant differentiator for buyers who want to work with the latest technology.

Sustainability is also a growing necessity for both buyers and suppliers; 78% of buyers often ask for sustainable materials from suppliers. However, only 20% of suppliers promote their sustainability practices as a leading factor to support the buying decision. In any case, material quality (26%) overtook sustainability (22%) as the deciding factor for buyers when sourcing materials.

This is the data by which business decisions are made today. This kind of insight, along with transparency in the material management lifecycle process and sustainability credentials, means buyers can see into supplier practices before initiating a relationship while suppliers can proactively promote their materials and practical commitment to sustainability.

“We believe that technology holds the key to next-level material sourcing. Both buyers and suppliers need to be as efficient as possible with their time; Material Exchange is their one-stop ecosystem to make material sourcing faster and easier. And if they can’t find something in particular, we have experts standing by to help.”

Darren Glenister, CEO, Material Exchange

Digital Transformation in Material Sourcing

The concept of digital transformation, or proactive organization-wide improvement to benefit customer experience, has gone mainstream and has now reached the material sourcing industry. The greater business landscape has become digital, which has increased the need for speed and agility supported by technology in every market sector. The sooner material sourcing moves to a digital-first supply chain, the faster we accelerate go-to-market potential and, ultimately, benefit end-customers. At the same time, digitizing the material sourcing supply chain also helps to conserve resources which protects the planet.

Revolutionizing the supply chain means sensing and delivering on trends, expanding the reach for both suppliers and buyers, and providing a one-stop ecosystem for the entire process, which requires integrated technology that communicates across the entire material supply value chain.

Even more, a frictionless technology platform needs to go beyond a holistic approach for business value management into being user-friendly and translatable in a variety of consumer languages. This may seem like a dream but it is the vision and real-world foundation of Material Exchange, a new global marketplace for faster fashion at less cost.

“We believe that technology holds the key to next-level material sourcing. Both buyers and suppliers need to be as efficient as possible with their time; Material Exchange is their one-stop ecosystem to make material sourcing faster and easier. And if they can’t find something in particular, we have experts standing by to help.” Darren Glenister, CEO, Material Exchange

Five Problems Solved

While some supply sourcing and material management systems have additional capabilities ‘bolted on’ to their core operations, Material Exchange has been built from the ground up with these elements in mind for our industry. Specifically, the Material Exchange platform solves the following five problems facing buyers and suppliers today.

Problem #1: Sourcing materials is complicated.

Problem #2: Products take too long to get to market.

Problem #3: Complex and siloed communication between buyers and suppliers.

Problem #4: Managing materials is fragmented.

Problem #5: Industry practices are destroying our planet.

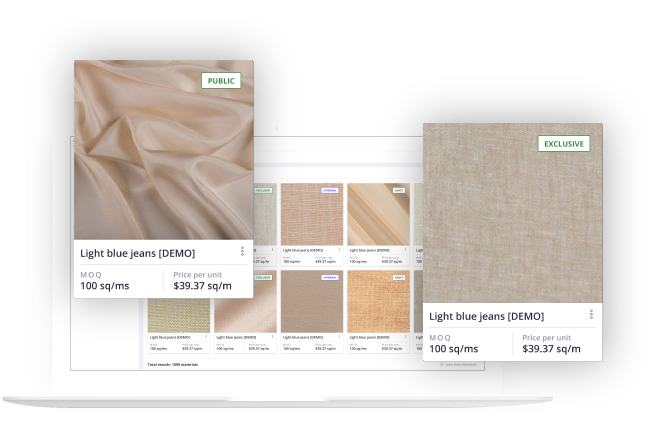

Essentially, Material Exchange is a secure B2B global platform that digitizes the material sourcing process and simplifies complex relationships between footwear and apparel brands and material suppliers. By transforming material sourcing – a traditionally dirty and wasteful process – through robust technology, including a one-stop virtual Marketplace, integrated user dashboards, SmartSearch, and personal deep-search experts, we are combining speed and sustainability for faster fashion and, ultimately, a safer environment. Suppliers no longer need to invest in expensive equipment to get quality images of their materials; our regional scanning hubs around the world will digitize their inventory in their format of their choice. And end-customers win by having products accessible sooner along with knowing the backstory on the materials in their products.

The Material Exchange platform was designed specifically for the footwear and apparel sourcing industry. Transforming traditional sourcing processes into virtual relationships streamlines communications. Using the Material Exchange platform to search for and promote materials streamlines the sourcing process. Being able to manage the sourcing, buying, and material management processes deliver accurate data for less human error and more time to build relationships.

By digitizing and data-organizing the sourcing materials process through an innovative membership model, buyers and suppliers now have a global marketplace that connects buyers with their supply chain, creates transparency through accurate data and communications, and promotes sustainability practices.

About the author

Lauri Kokkila, VP of Growth at Material Exchange, is responsible for developing and scaling Material Exchange’s Scanning Service globally.

Check out our webinars

We’ve got a wide range of informative, inspiring webinars in our library of events. Take a look to find one that sounds interesting. And feel free to reach out if there’s something you’d like us to cover that you don’t see!

Related content

Want to chat?

We’d love to hear from you. Reach out to see how we could work together.