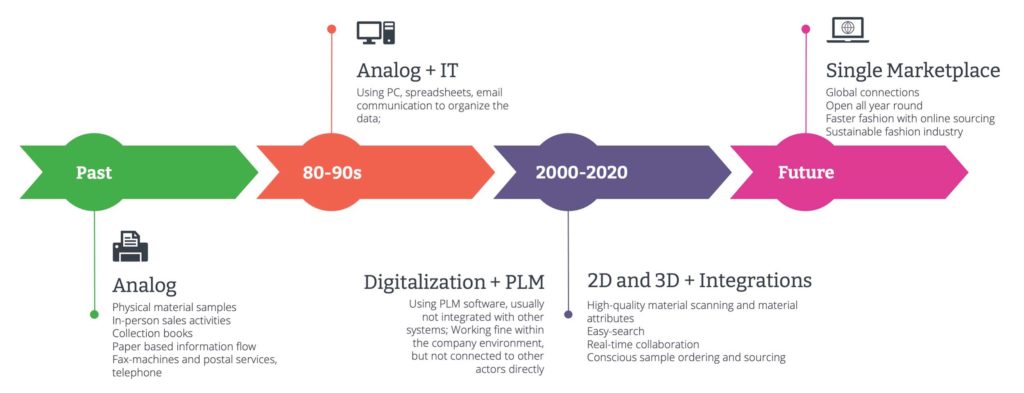

Material sourcing has evolved; we are currently in the fourth wave of industry maturity. No longer is it enough to rely on physical systems and fax machines to transact business. Today’s savvy industry buyers and suppliers know material sourcing today is about managing the entire lifecycle of material design, fabrication, and distribution with less cost and faster time-to-market using technology.

Technology can now be the heavy-lifter in streamlining the entire material sourcing process, beginning with a design concept or request through final delivery of the product. Focusing only on physical samples is limiting and results in excess waste for the planet.

The first wave: Analog

The first generation of material sourcing (pre-1980’s) focused on physical material samples, in-person sales activities, collection books, paper-based information flow, fax machines, snail mail through the postal service, and landline telephones.

Buyers would attend industry events armed with notebooks, pencils, tape, and scissors. They would collect fabric swatches in their notebooks to bring home to their teams. If something happened to the notebook, their efforts would have been for nothing. They might overnight the notebook to their team so they could compare notes and make decisions by phone or fax. Otherwise, they would travel with their notebook, delaying decision making and slowing their speed-to-market.

At the same time, suppliers needed to be present at those events with their full line. If they did not have a particular color swatch, textile, or accessory item, they might lose business. They shipped their products ahead of the event to allow for travel and setup time. If their shipment got lost, their show and, ultimately, their revenues suffered. They depended on phone and fax lines to receive orders; if someone wrote something down incorrectly or miscommunicated about a particular sample, it could be disastrous. Once the physical trade show was over, samples would often be trashed since it was more cost-effective than shipping them back to their facility.

Altogether, transactions had the limits of time and physical representation as well as pressure to deliver products (for both buyers and suppliers) despite high costs, travel, and potential waste. With brands and their customers demanding faster fashion, the material sourcing industry was under pressure to move from bricks (physical presence) to clicks (using digital tools).

The second wave: Analog + IT

Second-generation material sourcing (1980s-90s) still relied on physical samples and in-person events; however, using PC spreadsheets and email communication to update data about samples and transactions helped speed up the process and minimize mistakes related to transactions between buyers and suppliers. It was also during this period that basic websites became part of any company’s marketing presence.

Buyers could now see accurate data at a glance while suppliers could ensure information about their products was up to date. There was now a way to create a virtual paper trail instead of purely relying on physical documentation. Transactions became a little smoother. Buyers and suppliers had basic data to track trends. And, as technology evolved, it became clear there was a next level of material sourcing emerging.

The third wave: Digitizing for agility

The third generation of material sourcing maturity as an industry began in the early 2000’s. This is when industry visionaries recognized the capabilities of technology in product lifecycle management (PLM). Agility in meeting customer demands became a necessity. The focus was on using digital material lifecycle management to facilitate material transactions. At this point, PLM was not usually integrated with other systems; typically, PLM was limited to acting as an in-house ecosystem (exclusive of material suppliers and mills). Communication still relied on email exchanges and phone calls. Data analytics were used to tighten sourcing and marketing spend as well as time-to-market. End buyer focus was on quality products, regardless of production practices. Buyers were under pressure to find new suppliers and take advantage of emerging trends, while still relying on physical in-person events to see samples. Suppliers were under pressure to expand their customer base using physical samples and tradeshows.

Technology makes the world accessible to anyone from anywhere; a single marketplace is the next natural step in evolution. A single marketplace consolidates global connections, broadens buying options, and expands both buyer and supplier options around the world.

The fourth wave: Holistic experience

Since about 2010, we’ve been in the fourth generation of material sourcing maturity. The focus is not just on physical samples, customer acquisition and in-house systems but is also about the full range of material experience. End consumers care about saving the planet through sustainability so buyers face increasing pressure to source fabric from waste-sensitive suppliers who use sustainability practices in production. Technology has evolved for website presence, email marketing, social media marketing, and data analytics for intelligent decision-making.

Brands now need their customer audiences to perceive their brand holistically; that is, customers are buying based on their personal loyalties to causes, including sustainability. Brands risk their revenues by not including the end customer in their material sourcing process. So buyers need complete information not only about product samples but also about the practices behind their production. Suppliers need to demonstrate their commitment to waste reduction standards and sustainability practice certifications. In all cases, identifying, buying, and manufacturing the right materials cost-effectively is a key priority.

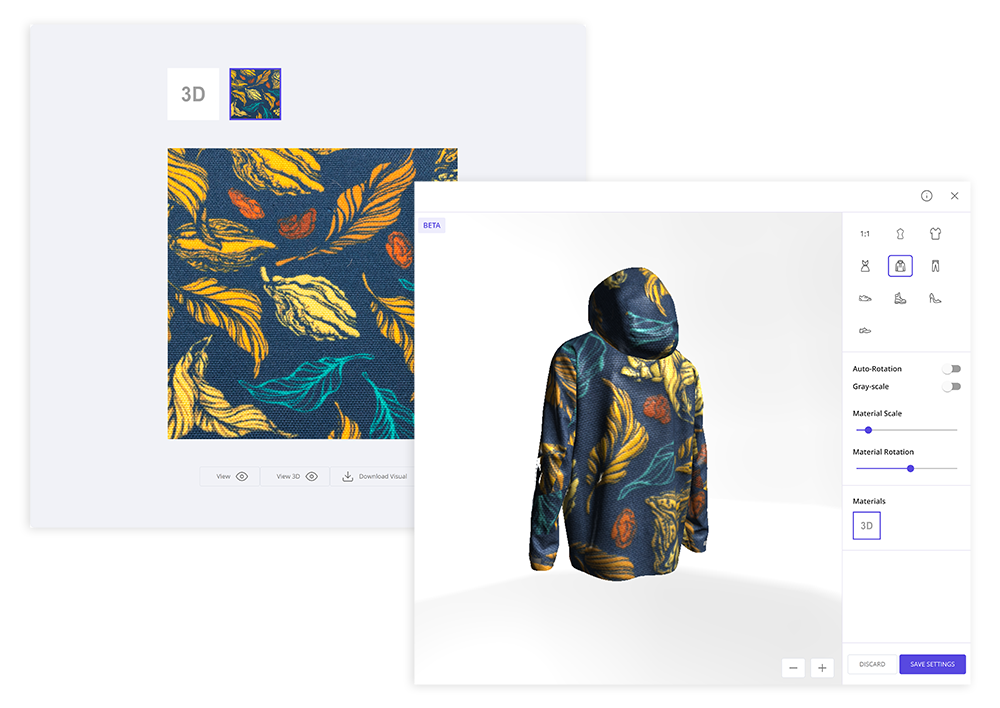

Technology systems are now integrated through the brand organization, including granting permissions to key stakeholders such as suppliers and manufacturers. Technology also allows 2D and 3D integrations to provide high-quality material digital scanning and attributes. Product designers can provide 3D models of finished products by using images alone (vs. physical prototype products). Brand teams for design, buying, and marketing can collaborate real-time using virtual portfolios. Buyers can easily find new suppliers and materials. There is an emphasis on conscious sample ordering and sourcing.

Both buyers and suppliers can now access and leverage information about material and customer history, buying and processing activities, and material preferences as well as accurate data about each material sample. They can use PLM to see how a material is progressing through the lifecycle of design, purchase, production, and distribution, as well as correlate that information to their inventory systems and end-product manufacturing. Buyers, designs, product managers, accounting, marketing, and business personnel can all see the status of a material at a glance through comprehensive technology systems. Suppliers can manage their inventory effectively, upload new materials for immediate access to buyers, and run digital promotions that can be seen around the world. Relationships between buyers and suppliers deepen through access, trust, and transparency.

The future: A single marketplace

Technology makes the world accessible to anyone from anywhere; a single marketplace is the next natural step in evolution. A single marketplace consolidates global connections, broadens buying options, and expands both buyer and supplier opportunities around the world.

Technology addresses global time zones by being accessible 24/7/365. Leveraging digital samples, discoverable with deep search capabilities, enables faster fashion. Material attributes, characteristics, and information are maintained for accuracy.

Having focused communications relevant to material sourcing in one place makes it simple to build and monitor relationships. Having buyer and supplier profiles ensures each is recognized for their commitment to quality, sustainability, and tracking trends.

In other words, we are all connected to help each other sustainably create better end products in fashion and footwear.

The time is now for Material Exchange to lead the next wave

To lead the Fifth Wave, Material Exchange delivers the technology platform designed specifically for material sourcing. This global sourcing marketplace enables buyers to find both the time-tested standards and hottest new materials available. In Material Exchange, buyers can create private portfolios for their teams; collaborate with suppliers around material needs; and monitor the entire material lifecycle.

At the same time, suppliers can upload high-resolution images for their products and include a thorough profile of each sample. They can showcase their industry experience, production standards, and sustainability certifications as well as run promotions for specific materials.

Additionally, Material Exchange now offers expert services to blend the technology platform with the human element to support buyers in being more efficient in their digital sourcing. These experts will help buyers find suppliers and materials faster and easier within the robust Material Exchange global ecosystem as well as source products that meet special requests and sustainability standards.

Material Exchange is the next-gen solution for material sourcing. This new generation of digitization brings buyers and suppliers together in a platform that bridges geographical gaps between them and transforms their material sourcing journey from piecemeal communications to a holistic experience. This type of connection is the new way of material sourcing – one that can change everything.

To get started today, claim your free membership as either a brand/buyer or supplier here.

About the author

Jessica Sundstrom, CRO, drives development and execution of a commercialization strategy for Material Exchange. Known for her can-do approach, clarity, and ability to get results, Jessica applies her deep experience to cut through the ‘noise’ of business and successfully power sales and marketing infrastructure and initiatives.

Check out our webinars

We’ve got a wide range of informative, inspiring webinars in our library of events. Take a look to find one that sounds interesting. And feel free to reach out if there’s something you’d like us to cover that you don’t see!

Related content

Want to chat?

We’d love to hear from you. Reach out to see how we could work together.