Supply chain disruptions, and what to do about it?

Uncertainty has been a trademark of 2025 so far for the fashion industry – and the trend seems to be on track to continue. Tariffs are the biggest force behind the sentiment, with contributions from climate change, legislation, and political instability thrown into the mix. It’s unclear how things will end up. For now, brands are managing as best they can with one phrase in the back of their minds: supply chain diversification.

Diversification is the process of a business spreading out its reliance to multiple suppliers, manufacturers, or geographical regions in order to minimize risks like economic trade blocs, supply shortages, and natural disasters. For fashion brands in business today, diversification is increasingly becoming a necessity.

While the tariffs first implemented by U.S. President Donald Trump largely focused on China, that is no longer the case as goods from countries like India and Sri Lanka are now also being highly tariffed. For the apparel sector (which is particularly vulnerable to tariff fluctuations), it’s difficult to know where to diversify their operations.

Practically speaking, brands are doing the best they can to stay one step ahead of the next round of tariffs by implementing flexible logistics; seeking multiple sourcing options; and adopting various digital tools to help guide their plans.

The right digital tool

Competitive brands know they need to be supply chain resilient – and getting there is a lot easier with the right technology. Digital tools can open up a realm of possibilities for creating improved efficiencies and processes for any business, and this rings even more true in the complicated, carbon-heavy fashion industry.

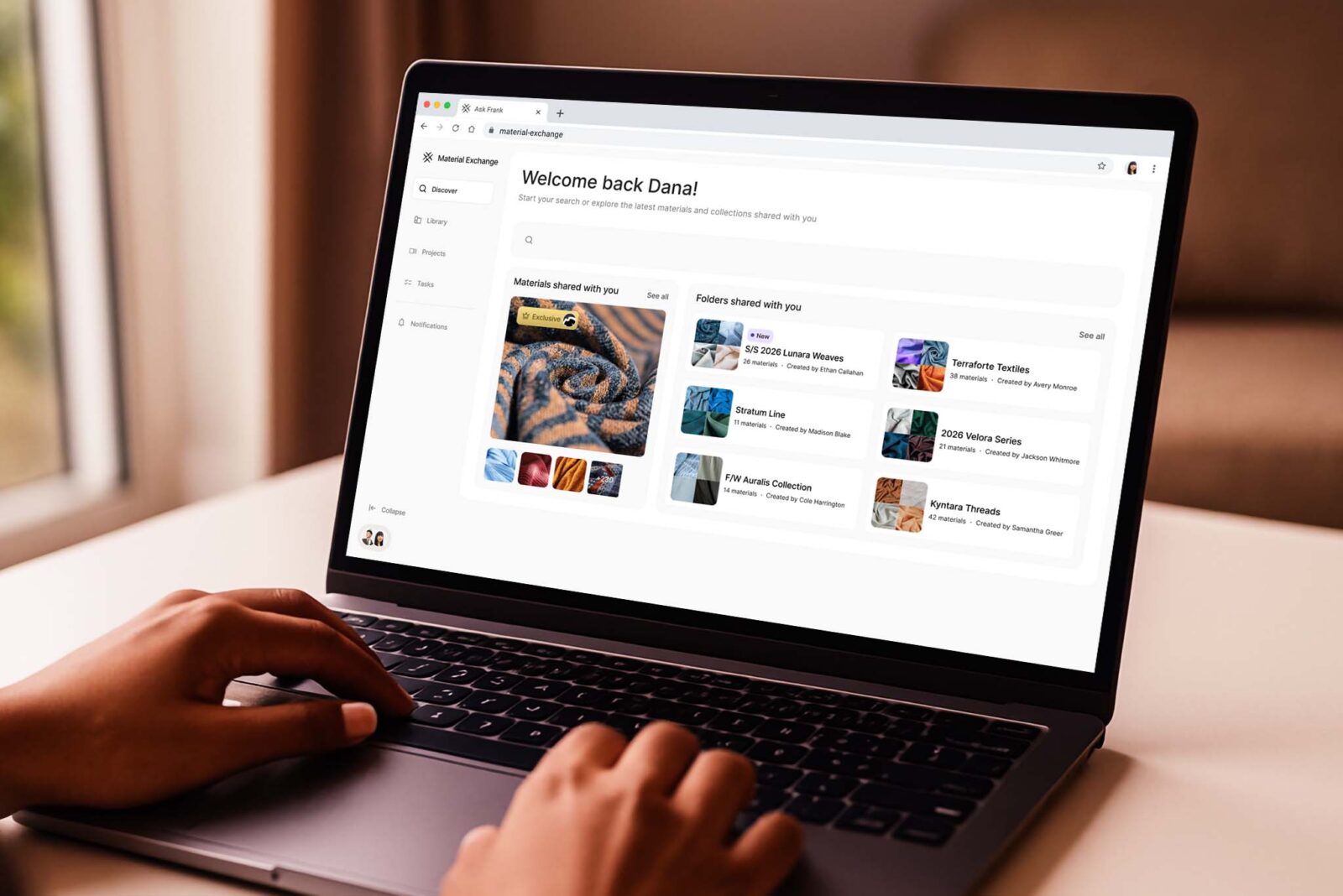

For many fashion brands, the digital tool they need is none other than our sourcing guru, Frank the bear. Frank has the ability to find the right materials, connect brands with suppliers, and manage all stages of sourcing. In short, he’s able to simplify the entire sourcing process.

What’s more, Frank’s latest partnership with the planet’s leading sustainability data platform Worldly offers brands another level of information on the materials they’re browsing and the factories that create them. More information enables brands to make confident sourcing decisions that are best for the future of their business – and the world.

Adjusting to a changing market

Consumers are savvier than ever when it comes to the full package of what they’re buying, and cost is no longer the only factor. Durability, transparency, sustainability, accountability – these all play a part in purchase decisions, and it’s reflected in how brands are running their businesses.

The short-term appeal of potentially saving a buck or two doesn’t measure up to the long-term benefits of sustainable actions. Worldly’s high-quality, granular data in Frank offers businesses a benchmark by which to move forward and meet these sustainability requirements (and expectations).

New PFAS legislation

For European brands, an additional consideration is the recently updated proposal by the European Chemicals Agency to restrict per- and polyfluoroalkyl substances in technical textile applications (among other sectors). These PFAS, often referred to as “forever chemicals,” have been used widely in the fashion industry to help dyes penetrate fabric evenly. Unfortunately, the chemicals have now been found in many people’s blood – hence the movement to decrease their abundance. With Frank and Worldly, brands can see exactly what makes up a given fabric so they can make the right choices for their business.

Whether it’s avoiding tariffs on clothing or following new legislation, brands are being forced to adjust their MO. Diversified manufacturing locations are one solution. Eco-friendly materials may be another. An increased reliance on 3D design instead of physical samples a third. And so many more. In all likelihood, a combination of measures will be necessary for most brands to find their sweet spot. And now, they can do it with Frank and Worldly. See how by booking a demo here: